Grade 7 - Structures and Forces

Section 1: Types of Structures

Structures are things that have a definite size and shape, which serve a definite purpose or function. To perform its function, every part of the structure must resist forces (stresses such as pushes or pulls) that could damage its shape or size. For example, a brick wall must be able to stand up to the force of the wind. The bricks at the bottom must support the weight of the bricks above. If a person climbs on top of the wall, the bricks must support that load.

Classifying Structures

One common classification divides structures into groups according to their origin. In this system, structures are divided into natural and manufactured objects.

1. Natural Structures

Natural structures are not made by people, they occur naturally in the environment. For example, feathers have a definite shape, and are made of many parts held together in a complex pattern. They have many functions: they insulate birds in cold weather, protect them from rain, and allow them to fly. Sand dunes have a characteristic shape and are made of many parts (sand grains) arranged in a particular pattern. They provide a home for small animals and insects and play a role in the desert ecosystem.

2. Manufactured Structures

Manufactured structures are made by people even though, many are modelled after natural structures. A fishing net, for example, has a design similar to that of a spider web.

Structures can also be classified by the way they are built. How a structure is put together, how it is shaped, and the materials making up the structure are all part of its design.

1. Mass Structures

A mass structure can be made by piling up or forming similar materials into a particular shape or design. Mountains and coral reefs are natural mass structures. Snow sculptures, dams, and brick walls are manufactured mass structures. So are foods such as omelettes, cakes, and breads. The structure is held firmly in place by its own weight. If parts of the structure are broken or worn out, the structure as a whole is not impacted significantly. Because of their large size and weight, mass structures must be carefully designed for them to perform their function effectively.

2. A Layered Look

Mass structures are not always solid, but are layered and have hollowed out areas for specific functions. A power dam and the Great pyramids of Egypt are a good examples.

Layered structures (such as a sand bag retaining wall) must meet certain criteria to function effectively:

- Must be heavy enough to stay in place

- Must not be too heavy to compact the earth unevenly below it

- Must be thick enough so it cannot be pushed out of place

- Must be secured/anchored firmly

3. Frame Structures

Frame structures have a skeleton made of strong materials that provide most of the structural integrity. Some objects, such as ladders, snowshoes, and spider webs, consist of only a frame. More complex objects may have other parts added to the frame, such as the pedals, gears, and brakes of a bicycle. The frame may be hidden beneath covering materials Frame structures are relatively easy to design and build, and inexpensive to manufacture, making them the most common construction choice. Examples include:

- Load-Bearing Walls: these are the walls that support the load of the the building.

- Partition Walls: these are the walls that divide up the space inside the building.

- A Bicycle frame supports the load it carries on the seat.

4. Shell Structures

Shell structures are objects that use a thin, carefully shaped outer layer of material to provide their strength and rigidity. An igloo, egg, cardboard box, egg tray etc are all examples of shell structures. They are strong and hollow. Even the bubbles in foams and cream puffs can be thought of as shell structures.

Shell structures have two very useful features. They are completely empty, so they make great containers. Because they have only a thin outside layer, they use very little building material.

Disadvantages of Shell Structures

- Tiny weaknesses like scratches on a glass jar can cause the whole structure to fail. Bubbles pop easily, balloons burst and glasses break easily when an unequal force is exerted on them.

- They are usually rounded in shape and cannot be made easily from flat materials.

5. Mixed Structures

Many objects are constructed using a mixture of several types of strucutres. For example, football helmets are shell structures, but the opening in front is covered with a strong frame. The combination of frame and shell construction protects the player while also allowing good visibility and ventilation. The mized structures in the helmet improves its structure and function. Airplanes are built around a metal framework, but the frame is not nearly strong enough to support the weight of the engines, fuel, and cargo. The metal 'skin' that covers the framework is stretched tightly and acts like a shell. Domed buildings usually combine frame and shell construction. The dome forms a shell, which gains strength from its curved shape.

Section 2: Describing Structures

Streuctures can be dscribed depending on their function. In some cases, the function is generalized because some strucutres do not perform just one specific function. Ask yourself, What is the structure supposed to do? What was it designed for? Some of the generalized functions include:

- Supporting - either its weight or an ecternal force

- Containing - to add substances inside. The structure needs to have the space and also the ability to protect the contents.

- Transporting - should contain space and the ability to move or be moved.

- Sheltering

- Lifting

- Fastening

- Separating

- Communicating

- Breaking

- Holding

Precise, measurable standards normally are indicated in the specifications the structure must comply with in order to perform its function/s.

Aesthetics describes the physical appeal of a structure. The best designs should be functional but als should 'look good' that is, 'aesthetically pleasing'. Aesthetics may be achieved by the shape, texture, color, type of material, symmetry and simplicity of the repeated pattern used in the design.

Safety - all structures are designed and built within an acceptable margin of safety (but usually, structures are designed with a built-in large margin of safety).

Cost: various components of a structure influence the cost. Addition of aesthetics features, adding extra strength to a structure costs money, as well as using more highly skilled workers and better materials might add the costs of developing the structures.

Structures should be designed to withstand conditions the designers hypothesize will occur. Good design is a compromise between a reasonable margin of safety and reasonable cost. Usually, totally unexpected events (such as tsunamis) will cause even the best structures to fail.

Materials

The properties or characteristics of different materials must match the purpose of the structure. Materials may generally fall under different types

1. Composite Materials

Composite materials are made of more than one material. For example, reinforced concrete is made using concrete and steel rods (rebar). If the concrete breaks the steel bars provide the structural support needed. Composite materials are designed to hold up to tension (pulling) and compression (pushing) forces.

2. Layered Materials

Layers of different materials (Tetra Pak) are pressed and glued together, combining the properties of the different materials. The layers are often called laminations.

3. Woven or Knit Materials

Spinning or twisting, looping or knotting fibres together gives material added strength. A loom is used to weave two or more pieces of yarn together in a criss-cross pattern to make cloth. Pressing, gluing, melting and dissolving are also ways to combine materials to gain strength.

Factors to Consider when choosing a material

- Cost - Costs should remain reasonable but should not compromise the function or safety of the structure.

- Appearance - The appearance influences aesthetics, but can also have an impact on functionality.

- Environmental Impact - does the structure impact the environment?

- Energy Efficiency - does the structure conserve energy?

Joints

Joints are used to fasten the structure together. Joints may be mobile (allow movement) or rigid (do not allow movement).

Fasteners - include nails, staples, bolts, screws, rivets and dowels. The holes made in the structure, by the fastener, actually weaken the structure. One fastener allows movement when the parts are pushed or pulled, whereas, more than one will make a more rigid joint - but, will also weaken it more.

Interlocking shapes such as those used on Lego fit together because of their shape. Dovetail joints in drawers, dental fillings and folded seams are some examples.

Ties, like thread, string and rope, fasten things together.

Adhesives, or sticky substances can also hold things together. Thermosetting glues (hot glue) and solvent-based glues (drying glue) strengthen the joint because of the bonds between the particles (like epoxy resins). Even the strongest adhesives can fail under extreme conditions and if the joint is stronger than the material it is joining, the material next to the joint can fail. Adhesives can also be a health hazard (like Super Glue - which dries very quickly when you use it - possibly bonding your skin if you touch it, or they can release harmful chemical vapours as they harden. Post-It Notes - An accidental glue (that turned into a huge success story). It did not meet the specifications, because it couldn't hold things together very well.

Melting - Pieces of metal or plastic can be melted together (welding, soldering - brazing or using chemicals)

Section 3: Mass and Forces

Matter is anything that has mass and occupies space. your pencil, your snack, the water inside your water bottle, the bircks used to make your classroom, the juice inside the juicebox... all these things are made of matter. However, light, heat and sound are not matter, because they dont occupy space.

We can describe matter using its properties. A property is a characteristic that you can observe for example, color, shape, size etc are some of the characteristics.

Mass: mass describes the amount of matter in an object. You can measure mass using grams (g) or kilograms (kgs). Mass is measured using a tool called A balance. A balance measures the mass by comparing the object to another object of known mass (standard mass).

A small cylinder of metal was used, as a standard, by which, to compare different substances. This standard (in the metric system) is called the primary standard of mass, and the amount of material in it is called one kilogram (kg). Smaller masses are measured in grams (g). 'Kilo' means one thousand (1000) and is equal to 1000 grams. Very small masses are measured in milligrams (mg). 1000 mg. equal 1 g.

Mass is a useful property to measure because it stays the same no matter where an object is located in the universe.

Forces and Weight

Force is a push or pull on an object. The standard unit of force is called a newton (N). (1 newton of force will stretch a thin rubber band, or will be what it takes to lift up a D-cell battery). A force meter (spring scale) is used to measue the amount of force - the pull of gravity - on a mass. To describe a force accurately, you need to determine its direction and size.

Weight is a force and should properly be measured in newtons. Sir Isaac Newton described the force that pulls objects together as the force of gravity. The gravitational forces between two objects depends on the masses of the objects and the distance between them. This gravitational force is called weight. Because gravitational force depends on the distance between two objects, an object's weight changes depending on where it is. (the farther away from the earth, the less the weight.

A force diagram is a simple picture that uses arrows to show the strength and direction of one or more forces.

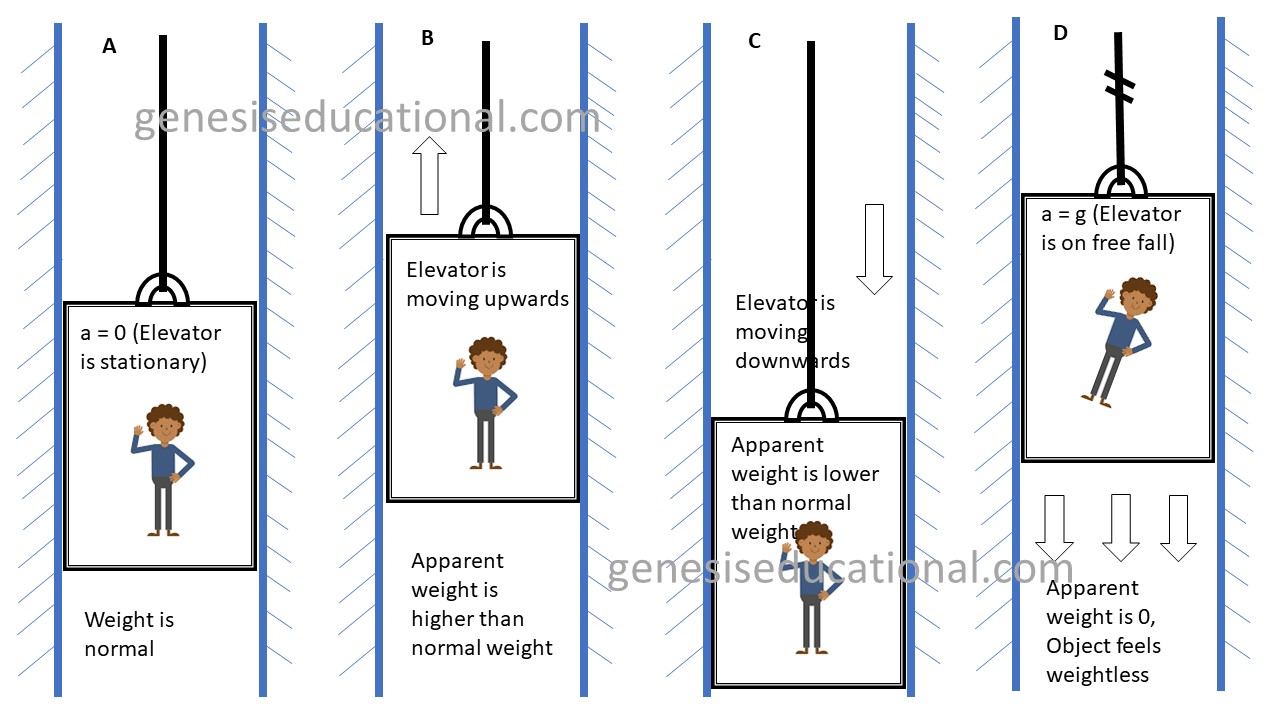

True weight and Apparent Weight

In physics, apparent weight is a property of objects that corresponds to how heavy an object is. The apparent weight of an object will differ from the weight of an object whenever the force of gravity acting on the object is not balanced by an equal but opposite normal force. An object that rests on the ground is subject to a normal force exerted by the ground. The normal force acts only on the boundary of the object that is in contact with the ground. This force is transferred into the body; the force of gravity on every part of the body is balanced by stress forces acting on that part.

The apparent weight can also differ from weight when an object is partially or completely immersed in a fluid, where there is an upward force from the fluid that is working against the force of gravity. Another example is the weight of an object or person riding in an elevator. When the elevator begins rising, the object begins exerting a force in the downward direction. If a scale were used, it would be seen that the weight of the object is becoming heavier because of the downward force, changing the apparent weight.

Section 4: Forces, Loads, and Stresses

External forces on structures are stresses that act on a structure from outside the structure. These forces produce internal forces, or stresses, within the materials from which the structure is made. These internal stresses can change the shape or size of a structure and is called deformation. This deformation can lead to repair of the damage to the structure, or failure of the structure.

External Forces

A dead load is a permanent force, acting on a structure. This includes the weight of the structure itself. A live load is a changing, or non-permanent force acting on a structure. This includes the force of the wind and the weight of things that are in or on a structure. Impact forces are a type of live load. They are things that collide with the structure exerting a momentary external force.

Internal Forces: include Tension forces stretch a material by pulling its ends apart. Tensile strength measures the largest tension force the material can withstand before failing.

Compression forces crush a material by squeezing it together. Compressive strength measures the largest compression force the material can withstand before it loses its shape or fails.

Shear forces bend or tear a material by pressing different parts in opposite directions at the same time. Shear strength measures the largest shear force the material can withstand before it rips apart.

Torsion forces twist a material by turning the ends in opposite directions. Torsion strength measures the largest torsion force the material can withstand and still spring back into its original shape.

A bending force is a combination of tension and compression, shear and torsion forces are also a combination of tension and compression forces.

Resisting Stress

The strength of materials can be traced to the forces between the tiniest particles of the materials.

Section 5: How Structures Fail

No structure is perfect. No material is perfect. If a great enough force acts on a structure, it will begin to fail. Even small forces, acting in a vulnerable place, can cause damage.

Levers

A lever is a device that can change the amount of force needed to move an object. When a force is applied to the effort arm, a large force, which can move the structure, is created. This can be intentional - like when a crowbar is used to move a heavy rock, or it can be unintentional - like when a gust of wind knocks down a flagpole.

Material Failure

1. Shear: minor weaknesses in a material can cause failure because the particles move farther apart and are less attracted to each other. This can be caused by compression.

2. Bend and Buckle: compression can also cause a material to bend and buckle - like a pop can that is stepped on. To prevent this reinforcements - stringers and ribs - are used to strengthen the structure.

3. Torsion: Twisting can cause material failure. When sections of the structure slide past each other the structure can crack or break in two. When the twisting action makes the structure unusable (even though it is not broken) it has failed because it has lost its shape.

Materials are designed to respond to external forces in various ways. For example:

Car bumpers are designed to buckle in a collision - as the metal fails, it absorbs some of the energy of the impact, which protects the occupants of the vehicle. Blades of grass on a sports field buckle as players land, which absorbs some of the impact forces on the players body.

Shear pins are used in outboard motors to prevent failure of the motor (when the propeller gets tangled in weeds, a shear pin breaks and the propeller becomes disengaged with the motor and gears. The clutch and automatic transmission in a vehicle take into account shear forces, which enable parts to slip past each other and produce a smooth ride.

Spinning wheels twist cotton or wool fibres so they lock together - making them strong enough to make cloth. Controlled twisting can also be useful in hair braids, ropes and telecommunication cables.

Metal Fatigue

Metal Fatigue (Definition - The phenomenon leading to fracture under repeated or fluctuating stress. Fatigue fractures are progressive beginning as minute cracks and grow under the action of fluctuating stress.) Metal breaks down over time and extended use. (They get bent and twisted over and over). The particles in the metal move further apart and have less attraction to each other. When a crack develops it weakens the metal - metal fatigue - and can eventually fail enen if a small force is applied.

Section 6: Designing with Forces

Engineers learn how to measure the different forces in order to create designs that will most likely prevent the structures from failing. There are three key methods to help structures withstand forces:

- Distribute the load (in this way no one part of the structure carries most of the load).

- Direct the forces along angled components (so that forces hold pieces together instead of pulling them apart).

- Shape the parts to withstand the specific type of force acting on them

Let us now examine some possible structural problems that may be observed:

Frame structures experience load forces which can push or pull them out of shape.

A Horizontal beam structure that is supported only at both ends will bend in the middle.

Solid beams are often too heavy and use too much material.

Flying Buttresses - are columns on the outsides of a structure that connect to the building near the top and are used to support the outer walls in much the same way that two sides of an arch support each other.

Strengthening Structures

All materials have their limitations. Materials can be strengthened or weakened as they are made. (Concrete - if the correct recipe is followed, the concrete can be very strong (compressive strength), but if the proportions are incorrect, the resulting concrete can crumble and fail, however it does not have very good shear or torsion strength. Shear forces can be fatal in metal if the shear strength is not analyzed when the metal is manufactured. The cooling process can eliminate almost all defects if it is done properly.

Frictional Forces

The force of friction resists movement between two surfaces that rub together. A brick wall is held together and kept evenly spaced with mortar, which helps to create large friction forces between each brick.

Friction is also important in frame structures. The friction between the nail and the wood keeps the nail in place and the joints solid. Different types of nails provide differing amounts of friction. Squeaks in floors are caused by fasteners that have loosened.

Friction between the ground and the bottom of a structure is an important design consideration. Friction holds the structure in place when external forces (wind) are acting on it. Too little, or too much friction can cause problems (moving chairs across the floor).

Section 7: Stable Structures

Center of Gravity

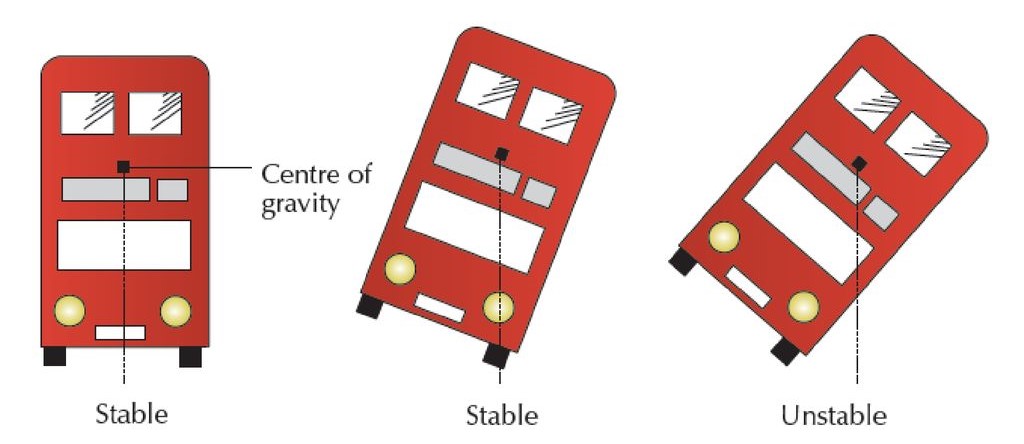

The center of gravity of a structure is important in order to stabilize the structure. The center of gravity is the specific point where all of the mass of the structure is evenly distributed around. The force of gravity acts on all parts of the structure and if all parts are evenly distributed around the center of gravity, then the structure will be stable. By locating the structure's center of gravity, an engineer can tell if the structure is stable or unbalanced.

Firm Foundation

The foundation upon which the structure is built must be stable, especially if it is moist, otherwise the compressive forces may cause the structure to tip and become unstable. If engineers and builders do not take into account the soil type and formations, the structures built may experience cracks in their foundations and walls.

Foundations can be constructed on solid bedrock, or, pilings (large metal, concrete or wood cylinders) can be used, if the layers of soil above the bedrock are loose enough. Some lightweight structures do not have to rest on the bedrock or, have to have a foundation that goes down very deep, because the ground doesn't freeze.

To determine whether a structure is balanced or is likely to fall, locate its centre of gravity and draw a line directly down toward Earth. If the arrow points to a solid foundation, the structure is balanced. If the arrow falls beside the foundation, the structure is not stable. If the ground beneath a structure is uneven and unstable, the structure may tip. When the imaginary arrow pointing down from the centre of gravity moves to a point beside the base of the structure, the structure will become very unstable.

Rapid Rotation

Every bicycle rider knows that it is harder to balance while moving slowly. The faster the wheels spin, the more the bicycle resists being tipped. Spin stabilization, the principle demonstrated by the gyroscope, is especially useful for objects that do not rest on a solid foundation. Space satellites need to keep their antennas pointed back to Earth and their instruments facing the proper location in space.